Tissue engineering strategies seek to overcome the limitations of current clinical approaches for the repair of damaged bone and cartilage tissues in order to restore quality of life to millions of people burdened by the pain and limited mobility associated with orthopedic defects. Most biological tissues are composed of a complex microarchitecture with well-defined extracellular matrix composition, mechanical properties, and cell populations. Due to its high level of complexity, in vitro replication of these tissues to engineer relevant organs or organoids is non-trivial.

With the rise in the popularity of 3D printing for tissue engineering, commercially available 3D printers to engineer these tissues have become more widely available and less cost-prohibitive. However, modular, standardized, and translatable democratized methods to fabricate scaffolds for complex tissues are not as widely available.

TR&D3 focuses on developing multi-material biofabrication strategies with the potential to recapitulate heterogeneous tissue by printing material composites and depositing growth factors in a gradient organization. The methods and materials produced by this TR&D can be replicated easily on most commercially available 3D printers. They provide robust tactics to recapitulate complex tissues while minimizing the need for specialized or custom hardware and software. Our strategies also work in concert with the other TR&Ds’ efforts to develop and characterize biologically active composite 3D printed scaffolds for osteochondral tissue engineering.

The methodologies and materials developed by this TR&D can be easily translated and modified depending on the intended engineered tissue application. These various strategies also support relevant Collaborative and Service projects by providing tunable platforms to fabricate scaffolds with specific design criteria for different materials, bioactive molecules, and cell types.

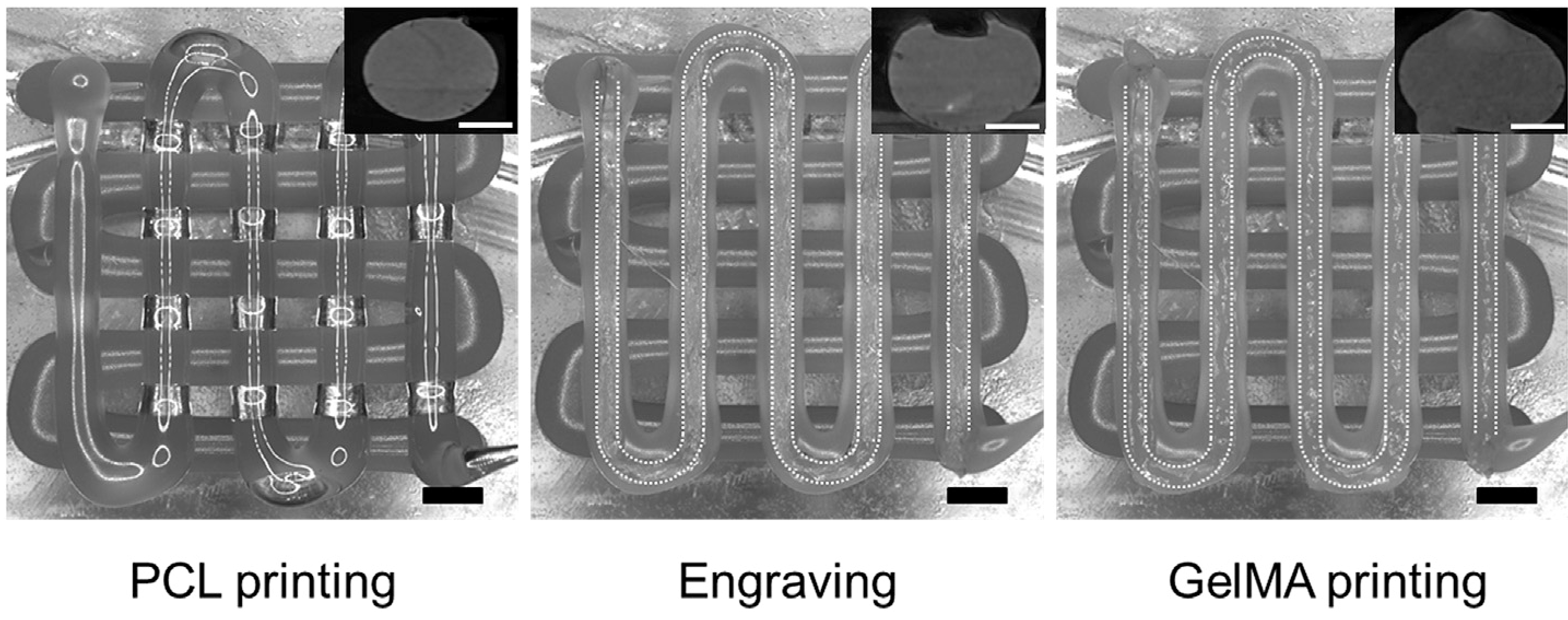

Optical images showing the steps to engrave and fill PCL scaffolds. First, each PCL layer is printed and allowed to solidify. Then, the surface of the PCL fibers is engraved by decreasing the needle offset to the desired depth of the grooves. Finally, GelMA is printed inside the grooves and crosslinked using UV light. Engraved areas are limited by white dashed lines. Scale bar: 1 mm. Image insets show the cross-section reconstruction of a fiber on each step of the engraving method. Scale bar: 400 μm. [Fiber Engraving for Bioink Bioprinting Within 3D Printed Tissue Engineering Scaffolds. Diaz-Gomez et al., Bioprinting, 18:e00076 (2020).]

Related Links

Images courtesy of Rice.